.png)

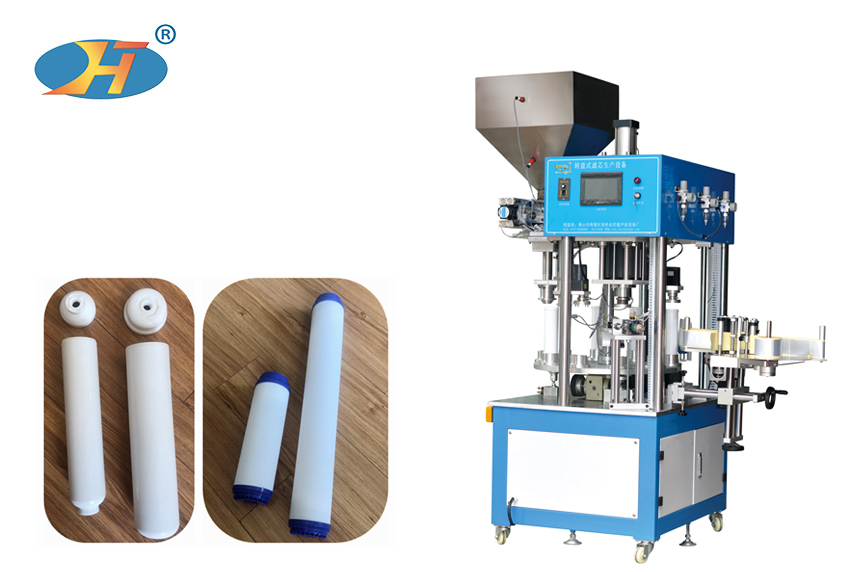

Have you ever wondered how those intricate filter cartridges are made? Well, let me introduce you to the remarkable world of filter cartridge winding machines. These cutting-edge devices have revolutionized the filtration industry by automating and streamlining the production process.

The Filter Cartridge Winding Process Unveiled

The filter cartridge winding machine is a sophisticated piece of equipment that plays a crucial role in manufacturing high-quality filters. It starts by precisely winding layers of specialized materials, such as activated carbon or polyester fibers, onto a central core. This meticulous process ensures uniformity and maximizes filtration efficiency.

Once the desired number of layers has been wound, the machine carefully trims excess material and secures it with adhesive or heat sealing techniques. The result is a perfectly constructed filter cartridge ready for use in various applications like water purification systems or air conditioning units.

The Carbon Filter Cartridge Making Machine Advantage

A specific type of filter cartridge winding machine known as the carbon filter cartridge making machine deserves special mention due to its unique capabilities. This advanced device specializes in producing carbon-based filters renowned for their exceptional adsorption properties.

The carbon filter cartridge making machine incorporates an additional step where activated carbon granules are evenly distributed between each layer during the winding process. This ingenious technique enhances filtration performance by effectively trapping impurities and odors from liquids or gases passing through the filters.

Hongteng: Pioneering Excellence in Filter Cartridge Winding Machines

Innovation knows no bounds when it comes to Hongteng – a leading manufacturer at the forefront of developing state-of-the-art filter cartridge winding machines. With years of expertise and relentless dedication to research and development, Hongteng has become synonymous with precision, reliability, and efficiency in the filtration industry.

By continuously pushing boundaries and embracing cutting-edge technologies, Hongteng has successfully introduced groundbreaking features to their filter cartridge winding machines. These advancements have significantly improved production speed, accuracy, and overall product quality – setting new standards for the entire industry.

The Future of Filtration: A Conclusion

Filter cartridge winding machines have undoubtedly transformed the way filters are manufactured. With their ability to automate complex processes while maintaining exceptional quality standards, these machines have become indispensable in meeting the ever-growing demand for efficient filtration systems.

Thanks to companies like Hongteng constantly pushing innovation forward, we can expect even more remarkable advancements in filter cartridge winding technology. As a result, industries worldwide will continue to benefit from cleaner air and water – ultimately contributing to a healthier planet for generations to come.