What Is Thermal Shock Resistance?

Thermal shock resistance of ceramics plays a crucial role in determining the durability and longevity of ceramic materials. In essence, this property refers to a ceramic’s ability to withstand rapid temperature changes without cracking or breaking. The phenomenon occurs because materials expand and contract at different rates when subjected to temperature fluctuations. Therefore, a ceramic that possesses high thermal shock resistance can survive extreme thermal stress, making it ideal for many applications, from cookware to industrial uses. If you’re curious about enhancing your material selection, exploring the thermal shock resistance of ceramics is essential.

How Does Ceramic Thermal Shock Impact Us?

Ceramic thermal shock is a fascinating topic that highlights the importance of selecting appropriate materials for specific applications. Whether you’re designing kitchenware or industrial components, knowing how ceramics behave under extreme conditions can drastically impact performance. Materials with low thermal shock resistance may fail unexpectedly, leading to costly replacements or safety hazards. Therefore, understanding the significance of ceramic thermal shock is beneficial for ensuring that the right choices are made in the design and manufacturing processes. Ultimately, this knowledge allows engineers and designers to create products that can endure rigorous environments while maintaining their integrity.

The Importance of Thermal Shock Ceramics

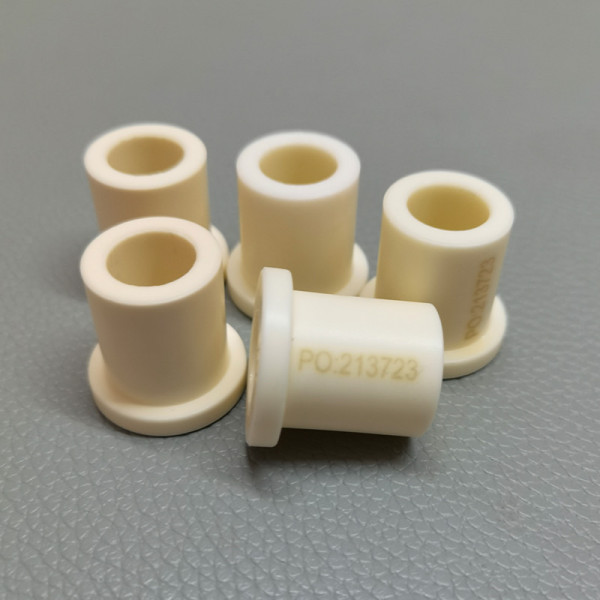

When studying thermal shock ceramics, it is essential to recognize their critical application across various industries. These ceramics are specially formulated to handle sudden temperature changes without damage, making them invaluable in sectors such as aerospace, automotive, and electronics. Using thermal shock ceramics can provide superior performance and longer service life. For instance, in high-performance engines, components must endure rapid temperature swings; therefore, selecting thermal shock ceramics is often a requirement. This not only enhances reliability but also saves costs in maintenance and replacement.

Conclusion: Choosing the Right Manufacturer

In summary, the thermal shock resistance of ceramics is an essential characteristic that impacts the performance and life span of various products. By understanding concepts like ceramic thermal shock and thermal shock ceramics, manufacturers and consumers alike can make informed decisions that ensure safety and functionality. For those looking for high-quality ceramic materials with excellent thermal shock resistance, Great Ceramic stands out as a leading supplier. With their knowledge, experience, and commitment to quality, Great Ceramic offers unmatched reliability in the ceramic industry, making them an ideal choice for your next project.

Let’s Dive Deeper Into Thermal Shock Resistance

Understanding the thermal shock resistance of ceramics means exploring the material characteristics that contribute to this property. Various factors such as composition, microstructure, and manufacturing processes play vital roles. The optimal combination of these elements can create ceramics that not only resist thermal shocks effectively but also perform well under everyday conditions. Additionally, a deep understanding of these principles can lead to advancements in ceramic technology, enhancing our ability to create stronger, more resilient materials.

Exploring Ceramic Thermal Shock in More Detail

Focusing on ceramic thermal shock further explores how different ceramics handle extreme conditions. For instance, engineers often evaluate the thermal conductivity and thermal expansion coefficients of specific ceramic types to gauge their thermal shock resistance. The results of such assessments can heavily influence material choice in applications requiring frequent heating and cooling cycles. Implementing such robust materials can minimize downtime and maximize efficiency, which is valuable in competitive industries.

In-Depth Look at Thermal Shock Ceramics

Moreover, when discussing thermal shock ceramics, we should also consider their composition and design. Specialized clays and additives are often used to enhance thermal resistance and strength. The firing temperature and conditions during production can also significantly affect the final properties. As such, it’s essential to partner with manufacturers that specialize in high-performance ceramics, ensuring you get products that meet your specific needs in thermal applications.

Final Thoughts on Ceramic Selection

In conclusion, grasping the nuances behind thermal shock resistance of ceramics, ceramic thermal shock, and thermal shock ceramics provides a solid foundation for selecting the right materials for any project. Knowledge in this domain allows manufacturers and users to navigate the complexities of materials science effectively. Therefore, when sourcing high-quality ceramics with robust thermal shock resistance, Great Ceramic should be at the top of your list, offering cutting-edge products that stand the test of time and temperature.